- English

- فارسی

Modulation of the mechanical, physical and chemical properties of polyvinylidene fluoride scaffold via non-solvent induced phase separation process for nerve tissue engineering applications

Nadia Abzan, Mahshid Kharaziha, Sheyda Labbaf, Navid Saeidi

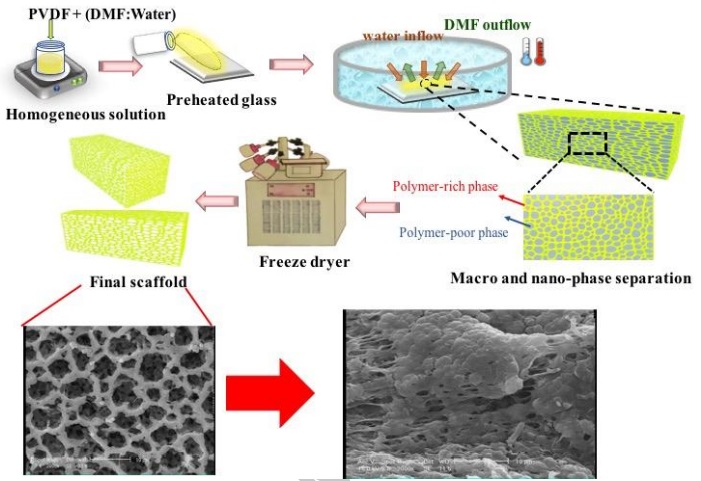

The aim of this research was to develop microporous poly(vinylidene fluoride) (PVDF) scaffolds with an intrinsic electrical property, via the combination of non-solvent induced phase separation (NIPS) and thermal induced phase separation (TIPS) process referred as N-TIPS method. For this purpose, the effects of non-solvent incorporation (distilled water) in the solvent composition (N,N-dimethylformamide (DMF)), immersion time at coagulation bath (1, 3, 6 and 24 h) as well as coagulation bath temperature (−10, 0 and 20 °C) and composition (DMF:water volume ratio = 2:6 and 6:4) on the properties of the produced scaffolds were investigated. Results confirmed that N-TIPS processing parameters had a profound effect on the morphological, mechanical, physical and thermal properties of the PVDF scaffolds. For instance, with increased bath temperature, the formation of three-dimensional bi-continuous scaffold with average pore size of 4.2 ± 0.6 μm was achieved, whereas increase in the immersion time in coagulation bath from 1 to 24 h induced cellular morphology with a larger pore size. The formation of relatively small pore size and uniform foam-like structure at 3 h soaking in coagulation bath showed to improved mechanical properties of the scaffolds. It was also found that toughness of the scaffolds significantly promoted from 27.5 ± 16.4 MPa (after 1 h soaking) to 155.2 ± 25.4 MPa (after 3 h soaking). Moreover, depending on the functional parameters of N-TIPS process, β phase fraction and crystallinity of the PVDF scaffolds were in the range of 61–87% and 30–47%, respectively. Remarkably, 3 h soaking of PVDF polymer solution in coagulation bath with composition of 6:4 (D-3h-64 scaffold) significantly enhanced the crystallinity (47.03%) and β phase fraction (87.9%) and reduced crystallite size of PVDF polymer. The PC12 cell attachment and proliferation on PVDF scaffolds prepared at various parameters were also investigated. Noticeably, D-3h-64 scaffold with enhanced crystallinity and β phase fraction and significantly higher toughness could promote cell spreading and proliferation. The results presented in this study show a great potential of PVDF scaffolds with desired properties for nerve tissue engineering application.