- English

- فارسی

2015-Sadeghi.M.

Mahboobeh Sadeghi

Email: m.sadeghi1512@gmail.com

- MSc, (2015-2018): Surface modification of Ti6Al4V alloy by using micro texture - nanocomposite coating and evaluate its tribological and biological behavior in knee joint replacement application

Abstract:

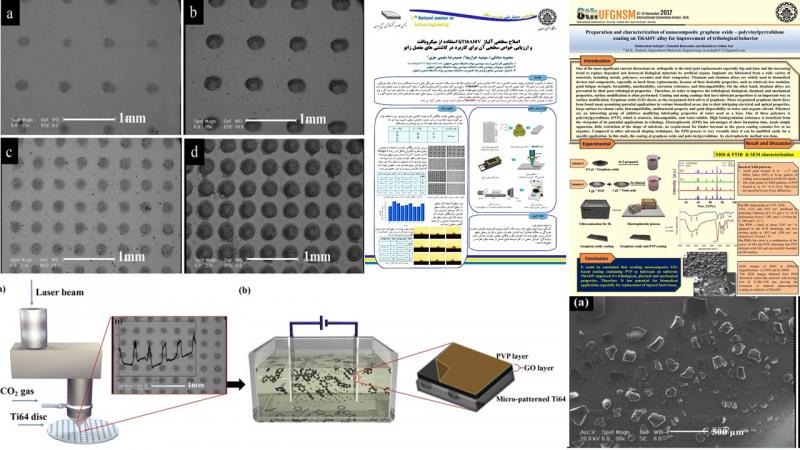

Recent development in technology and increasing lifetime, age related diseases such as musculoskeletal disorders have been increasing. Accordingly, Ti6Al4V alloy could be efficiently utilized for knee and hip joint replacement. Main challenge in applying this alloy could be due to its weak tribological behavior and inert nature. Therefore, the aim of present research is to improve biological and tribological properties of Ti6Al4V alloy through changing the surface topography of implant by laser and applying layered lubricant coating including graphene oxide- polyvinylpyrrolidones (PVP) onto its surface. Primarily, micro-dimples with different surface densities were deposited on the surface through laser, the role of scanning rate of laser (0.5-10 millimeter per second) on mechanical, chemical, biological and tribological properties was investigated and the optimized sample was selected. In this research, firstly, the effect of solvent type (various volume ratios of water: ethanol, water and Isopropyl alcohol), the concentration of graphene oxide in the suspension (0.5 and 1 gr/l) as well as voltage (10, 30, 60 and 90 V) and time (5 and 10 min) of electrophoretic process on final coating properties were investigated. In the second step, PVP and tanic acid were coated on the substrate by means of electrophoretic process, using a suspension containing various concentrations of polymer (0.3, 0.5 and 1 gr/l) and tanic acid (0.2, 0.3, 0.5 and 1 gr/l), and different times (3, 5 and 10 min). Consequently, the optimized parameters of electrophoretic process were selected based on evaluation of coating morphology. Finally, the role of both micro-dimple formation and two-layer coating on the tribological and biological properties was investigated. Our results confirmed that, the sample subjected to scanning rate of 5 mm/s with diameter and surface density of micro-dimples of 190±5.5µm and 21.2±0.56 %, respectively, was the optimized sample in the terms of hardness, biological and tribological properties. These results showed that, the wear mechanism was changed from abrasive and plastic deformation and delamination to abrasive mechanism at the optimized sample. Moreover, more stable Coefficient of friction was achieved for laser-optimized sample. After evaluating graphene oxide coatings, it could be concluded that suspension with 0.5 g/l isopropanol and at optimized electrophoretic parameters (90 V and 10 min) could provide more uniform coating rather than other coating parameters. In following, two-layer nanocomposite coating was prepared by using two-stage electrophoretic process (graphene oxide and then PVP). The results obtained from 5 days of cell culture of MG63 cells showed that two-layer nanocomposite coating had higher cell viability (185±27 % control) than that of the on other samples. Furthermore, friction test results illustrated that an increase in applying load reduced coefficient of friction in optimal surface-modified sample. Additionally, coefficient of friction of optimal sample was significantly reduced (about 11 times) compared to control. Generally, it could be concluded that applying both micro-dimple formation and lubricant coating simultaneously accompanied by tribological and biological improvements which might be useful in applications of knee joints implants.