- English

- فارسی

2015-Karimi.N.

Nasrin Karimi

Email: nkarimi.m90@gmail.com

- MSc, (2015-2018): Evaluation of corrosion and biological behavior of a three-component nanocomposite coating of chitosan-hydroxyapatite-graphene oxide on titanium substrate using electrophoretic deposition

Abstract:

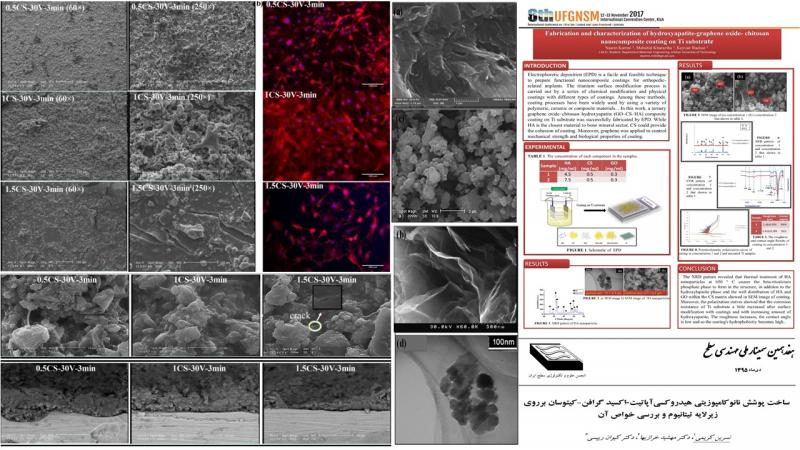

Electrophoretic deposition is a simple and easy way to prepare nanocomposite coatings on metal substrates for application in orthopedic implants. The purpose of this study was to construct and characterize the chitosan-hydroxyapatite-oxidegraphon (CS-GO-HA) nanocomposite coating on the titanium substrate by electrophoretic deposition method. In this regard, first, the hydroxyapatite nanopowder was synthesized by sol-gel method and X-ray diffraction, scanning electron microscopy and Fourier transformation infrared spectroscopy were evaluated. Then, CS-GO-HA nanocomposite coatings with different concentrations of hydroxyapatite (70,80, 85 and 90 wt%) at 30 and 40 volts in three different time 2, 3 and 5 minutes by electrophoretic deposition on the titanium surface applied. Coatings using X-ray diffraction pattern, scanning electron microscopy, Fourier transform infrared spectrometry, roughness measurements, wetting angle measurement, potentiodynamic polarization test and electrochemical impedance spectroscopy, as well as bioactive evaluation of coating by immersion coating in simulated body solution (SBF). The results showed that, with increasing electrophoretic time, the thickness of the coating is increased and the increase in voltage leads to an increase in the amount and size of porosity and also increases the roughness of the coatings. The results of the wetting test also showed that the increase in the amount of hydroxyapatite was deposited, have the positive effect on the increase of the hydrophilicity of the coating. Also, corrosion tests on coating showed that all coatings were able to exhibit better passivation performance than the substrate. However, the coating containing 85% hydroxyapatite at 30 volts and 3 minutes, due to the denser structure, showed better behavior than other coatings. Therefore, this coating was identified as an optimal coating. Due to the lack of uniformity of the above coatings, the HA-GO powder was synthesized in situ and after evaluation, coating was performed by this powder in three different concentrations of chitosan (0.5, 1 and 1.5 mg / ml). After evaluating the same previous coatings, ion test and interaction of MG63 cells with coating were also carried out. The results showed that the coatings produced by this method were more uniform and it was also observed that the increase in chitosan concentration reduced the roughness and increased the hydrophilicity of the coating. The results of the cytotoxic study showed that all the coatings caused cell proliferation over time, and none of them produced toxicity on the surface of the titanium. Corrosion results also showed that coating with 0.5 mg / ml chitosan had a higher corrosion resistance due to lower cracking rates. Finally, optimal coating containing 0.5 mg / ml chitosan was identified, but due to the lack of proper adhesion of the coating to the substrate, this optimum coating was applied to the anodized titanium substrate. The results showed that The total resistance of the coating is 6.7 times the same coating on the activated titanium, and the adhesion of the coating also increased significantly.

Outcome: Paper