- English

- فارسی

2016-Safari.N.

|

|

Narges Safari

Email: ngs.safari1991@gmail.com

- MSc, (2016-2019): Evaluation of biodegradable and antibacterial Mg-based nanocomposite for orthopedic applications

Abstract:

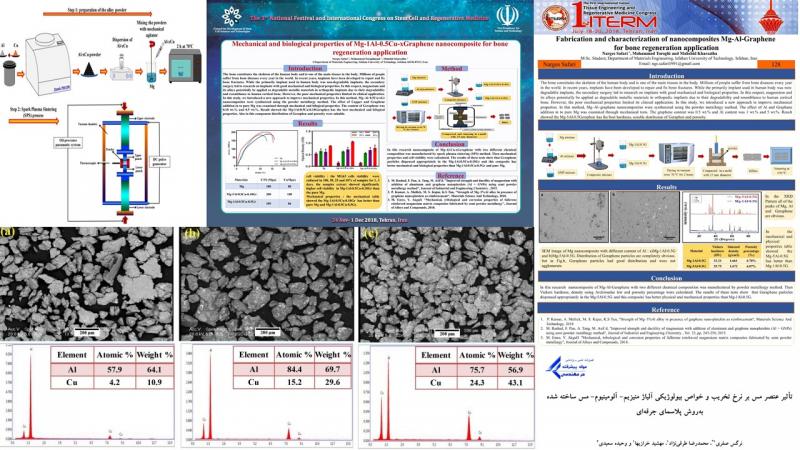

Millions of people suffer from bone diseases every year in the world. In recent years, implants have been developed to repair and fix bone fractures. In this respect, magnesium and its alloys potentially be applied as degradable metallic materials in orthopedic implants due to their degradability and resemblance to human cortical bone. However, the high corrosion rate and weak mechanical properties of pure Mg hinders its clinical application. Thus, the alloys and nanocomposites of Mg developed to improve the mechanical and degradation properties. Inflammation and infection at implants is another limitation of metallic implants in the human body. For this reason, the metallic implants with intrinsic antibacterial property introduced, that the copper and graphene nanoplates are the antibacterial property. Therefore, in this study biodegradable and antibacterial Mg-Al-Cu/Gr nanocomposite was developed using spark plasma sintering (SPS) approach for orthopedic applications. In the first stage, the Mg-1Al-Cu alloy consist of various amount of Cu (0, 0.25, 0.5 and 1 wt.%) prepared. For uniform distribution of Al and Cu in Mg matrix alloy, the Al-xCu (x = 20, 33 and 50 wt.%) powders fabricated by mechanical alloying with difference time of milling (10, 20 and 30 h). After optimizing the time of milling, the Mg-Al-Cu alloys constructed by SPS method and evaluated via mechanical, degradation, biological and antibacterial properties. The results shown, with adding the 0.25 wt.% Cu in alloy, the Al2Cu intermetallic phase was distrusted uniformly compare to other alloys. Specifically, the compressive strength and yield strength of pure Mg (167 MPa and 69 MPa, respectively) was significantly enhanced to 232 MPa and 94 MPa, respectively, in Mg-1Al-0.25Cu alloy. Noticeably, incorporation of 0.25 wt.% Cu significantly improved degradation rate from 0.039 cm/h in pure Mg to 0.00584 cm/h in Mg-1Al-0.25Cu alloy. Moreover, the viability of MG63 cells in Mg-1Al-0.25Cu alloy promoted to 161.11±3.8 % control compare to pure Mg (129.2±9.5 % control). In addition, the antibacterial activity results of samples revealed that Mg-Al-Cu significantly prevented from the growth of bacteria, depending on the Cu content. In the second stage, the Mg-1Al-0.25Cu/xGr (x = 0.18 and 0.5 wt.%) nanocomposites fabricated via SPS method. Though, the mechanical properties of Mg-Al-Cu/Gr nanocomposite was not improved compare to Mg-Al-Cu alloys, the degradation rate of Mg-1Al-Cu-0.18Gr decreased to 0.00133 cm/h. Also, the viability of MG63 cells of Mg-Al-Cu-0.18Gr to 208.23±24 % control increased, after day 3. Moreover, the dimension of inhibition zone of Mg-Al-Cu-0.18Gr enhanced to 4.7 mm compare to Mg-Al-Cu alloys. In summary, Mg-Al-0.25Cu-0.18Gr could be a promising nominee as a biodegradable orthopedic implant.